A Zeta Gomma is an international company, established almost 50 years ago in Sassuolo (MO), in the heart of one of Italy’s most important industrial areas (for ceramics in particular).

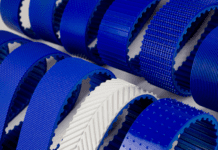

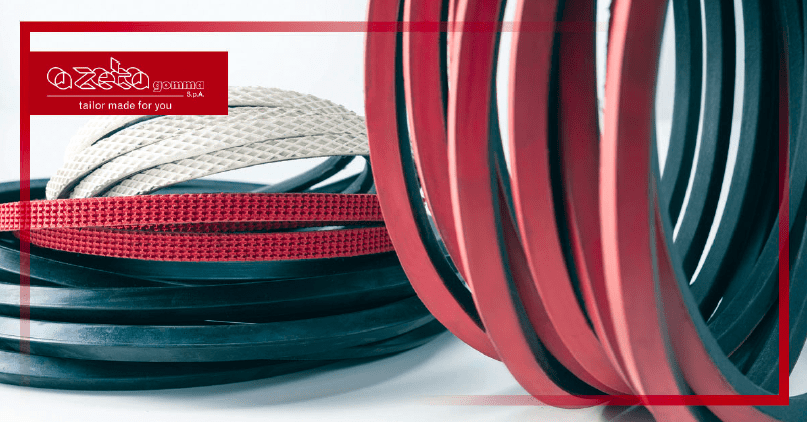

It has a wide range product such as power transmission belts, v-belts, and conveyor belts (in rubber, PVC and PU), as well as thermo-weldable belts, hoses for roller coatings, rubber sheets, moulded products, technical items and equipment for pressing, welding and joining belts. The main features of A Zeta Gomma are the top quality production and the versatility to meet every specific customer need and durability under all conditions of use, even the most severe.

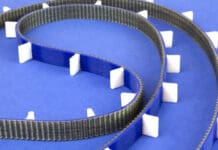

A distinguishing point of A Zeta Gomma’ s excellence is the M.E.C.® ProfilBelt range, completely customised belts with special rubber coatings.

Thanks to its experience in moulding and a fully equipped internal vulcanising department, A Zeta Gomma is able to create a wide range of coatings in order to adapt the belts to many applications. The coatings differ in terms of the type of rubber, colour and shape, and are perfectly tailored to each customer’s requirements.

M.E.C.® ProfilBelt optimise the conveyance of materials on horizontal, sloped, or vertical, and their versatility is due to their production features: endless coatings can be vulcanised with different types of rubber, in different colours and shapes, and with smooth, honeycombed or rhomboidal surfaces which can also be made according to the customer’s own specifications. In all conditions of use, M.E.C.® ProfilBelt guarantee maximum strength and reliability, in true A Zeta Gomma style. Particularly for this type of belts the great value to be considered is the free set length, which the M.E.C.® ProfilBelt range ensures at the highest levels, providing a leading service, up with the technological developments of machines in the various applications fields.

The great tensile strength of these high-performance belts is combined with optimal flexibility, to minimise the wear and tear of the machines on which they are used. The belts are customisable in every aspect: from the preliminary consultation to the creation of the design, preparation of the sample and final production, thanks to the know-how of the company’s internal technical department. This is possible as a result of the A Zeta Gomma’s extensive and comprehensive experience in the vulcanising sector: the company is able to rubber or silicone coatings through truly “endless” vulcanisation, to ensure the highest levels of quality. The hot vulcanised coating on the belt grants a friction for the maximum grip on the conveyed material. The selection of the raw materials is based on the experience acquired by A Zeta Gomma in its numerous years of belt manufacturing, together with constant input from customers, with whom it has almost daily consultations, leading to continuous improvement of the product.

A Zeta Gomma ensures a large availability of its products thanks to the 20,000 m² of floor space, including commercial headquarters, three production units and one warehouse, with 80,000 items immediately available, in order to ensure high standards of product customisation, industrialisation and distribution. A distinctive feature of A Zeta Gomma is the services it offers to its customers: thanks to the direct in-house production of its own item range, A Zeta Gomma is able to meet all customers’ needs, no matter how particular or complex. The services begin with customised design support and are always in line with the customer’s requirements and expectations. Thanks to its own specialised staff. A Zeta Gomma is also able to make specific products from drawings supplied by the customer or design them in collaboration with the customer. This ensures that each A Zeta Gomma product offers the highest level of quality, with no margins of error. More information about A Zeta Gomma can be found at www.azetagomma.com.

This article is published in MOTION+DRIVES Oct-Nov-Dec 2021 issue.

Download the .pdf version or Read the eMagazine