The trend towards greater industrial and production automation has clearly been boosted by the need for social distancing and the problem of finding workers during the pandemic. However, the greater the automXation, the more the pressure to ensure top efficiency, productivity and return-on-investment for conveyor lines. Very often, the only way to achieve this is to install customized belting to match each application’s exact needs.

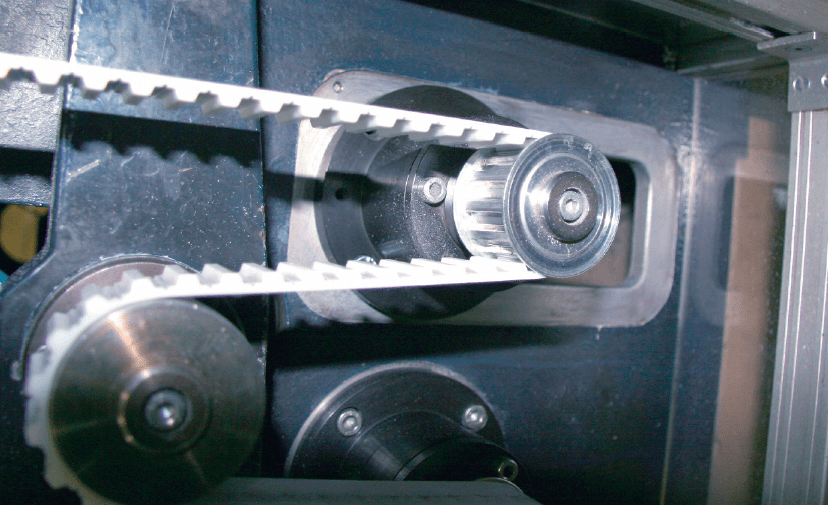

As the global pioneer of numerous belting innovations for over 75 years, Habasit knows that customized solutions are key to our customers’ success. With automation ramping up, timing belts are particularly in focus, including our HabaSYNC® truly endless flex timing belt range.

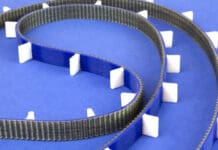

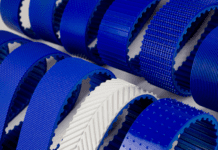

HabaSYNC flex timing belts are ideal for synchronized parallel and linear conveying, and precise positioning of heavy loads. Manufactured with helically wound cords, they provide double the strength of joined endless belts, and can also be used efficiently in high power transmission applications. Key features include resistance to abrasion, hydrolysis, UV light and ozone, oil and grease, and some acids and caustic solutions.

HabaSYNC flex timing belts are produced from a standard sleeve width of 150 mm / 5.9″. But it’s our unique slitting lane technology and ability to arrange the cords in the sleeve that ensure exactly customized belt widths.

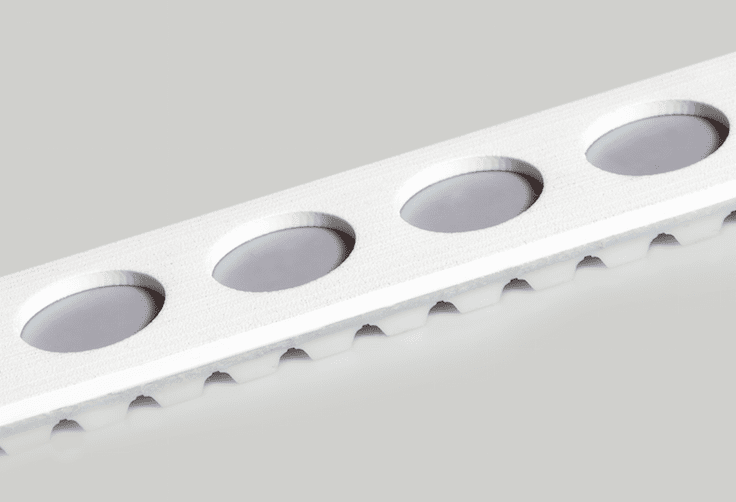

The result: high-quality belts in the correct width with clean, homogeneous edges. Another benefit is the option to arrange the cords so that holes can be punched, or screws positioned, precisely where needed.

Several of these customizations appeared in a recent case, when a canning industry OEM requested a 200 mm wide flex timing belt with special thickness tolerances and large diameter holes, using specific slitting lane widths. The belt had to lie flat, be durable, resist regular stamping, and index the product accurately. Furthermore, it needed to be supplied within just eight weeks.

Rising to the challenge, Habasit engineers in three countries coordinated the production of two flex sleeves, arranged longitudinal welding to make the 200 mm width, used water jets to cut the holes, delivered in seven weeks – and received enthusiastic feedback on the belts’ superb quality and fast delivery.

Another case featured very narrow belts of 7 mm width for a beverage industry OEM. The requirement was for FDA-approved belts for a PET preform inspection application using camera scanning, with a non-marking cover, adhesive surface, higher thickness, and dark colour.

Thanks to Habasit’s extensive customization capabilities, we delivered these narrow, fully FDA/ EU-approved belts with an exclusive, very thin FDA textile on the teeth, on black belts extruded with a high back. The new belts not only eliminated marking on the preforms, the application also ran faster.

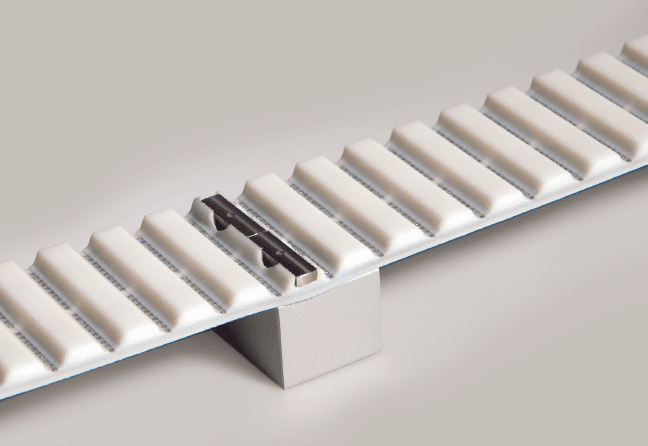

As the above cases show, another unique advantage of Habasit’s flex timing belts is that for thicker belts, Habasit can extrude TPU during manufacture (to 16 mm). The advantages of extrusion were clearly illustrated when a biscuit manufacturer asked Habasit to replace its welded-cleat packaging lines, which were suffering frequent belt replacements and unscheduled repairs due to cleats breaking off. Our response: FDA-approved monolithic timing belts with precision milled integrated cleats, which delivered five times longer belt lifetimes, lower costs and higher productivity.

When extrusion is not an option, cleats (TPU profiles) can be welded onto the conveying side of a timing belt in any number, shape, or placement. We also offer a unique false teeth design for profile attachments that delivers more robust construction, greater design flexibility, and better durability than other options available.

HabaSYNC flex timing belts offer 14 pitch designs, six cord options, different TPU materials, multiple colors (including an exclusive white), various cleat options, longitudinal profiles, and advanced fabrication facilities for milling, grinding and perforating. Belts can have friction-reducing, wearresistant polyamide fabric on the tooth side, which is also available with antistatic properties. With over 100 cover options available, we offer the largest choice on the market. As well as the fastest delivery.

Whatever your challenge, Habasit can create a customized solution to meet it.

This article is published in MOTION+DRIVES Oct-Nov-Dec 2021 issue.

Download the .pdf version or Read the eMagazine