The fitness industry is no longer just about strength and endurance; it’s also about the user experience.

Today’s gym equipment must meet the evolving demands of elite athletes, everyday users, rehabilitation professionals, and their patients, all of whom expect seamless motion, reliability, and comfort during every workout.

The performance of this equipment hinges on the precision of its components; at Megadyne, we’re proud to power that performance.

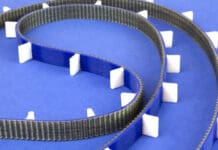

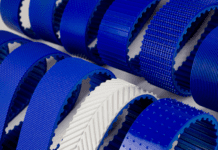

From treadmills to cross-trainers, our belts are engineered to offer more than just mechanical functionality. They are designed to meet high-level requirements: grease-free surface, silent drive, long service life, smooth starting and running, maximum efficiency, and reduced dimensions.

Every machine has its specific requirements; we do our best to meet all these needs and ensure a great workout experience.

Why is it important to choose the right belt?

Most types of equipment used in the fitness industry — such as treadmills, exercise bicycles, steppers, and cross-trainers — all contain some type of drive system that utilises different types of belts or chains.

The drives on the equipment at the upper end of the market are required to operate at very low noise levels while functioning at a high level of smooth, progressive action.

A drive that does not operate well creates a negative experience for the user, giving the impression of a low-quality machine.

Treadmill case study – When the drive belt slows the run

A manufacturer of high-end treadmills contacted us for assistance with drive issues on a treadmill they were developing for the elite athlete and medical rehabilitation segment of the fitness market.

In their application, the slats that make up the conveyor belt (where users run on) were attached directly to the drive belts.

The belts supplied by a competitor experienced various problems, including drive noise and erratic movement requirements. There were also issues with the slats becoming loose and eventually detaching from the drive belts.

Continue reading to see the solution – download the case study.

Trainer case study – Cross-trainer power loss: a pattern worth breaking

An exercise equipment manufacturer was experiencing challenges with the belt drive of a high-end cross-trainer they were developing for the fitness centre market.

An exercise equipment manufacturer was experiencing challenges with the belt drive of a high-end cross-trainer they were developing for the fitness centre market.

The manufacturer tried chains, PV-belts, and timing belt drives, but all these solutions either caused too much noise or could not properly transmit torque.

Download the full success story to see how Megadyne solved the issues.

In both cases, Megadyne didn’t just solve a problem. They helped the partners regain market confidence, improve end-user satisfaction, and bring a higher-performing product to market.

Need personalised support? Visit the website and contact Megadyne!