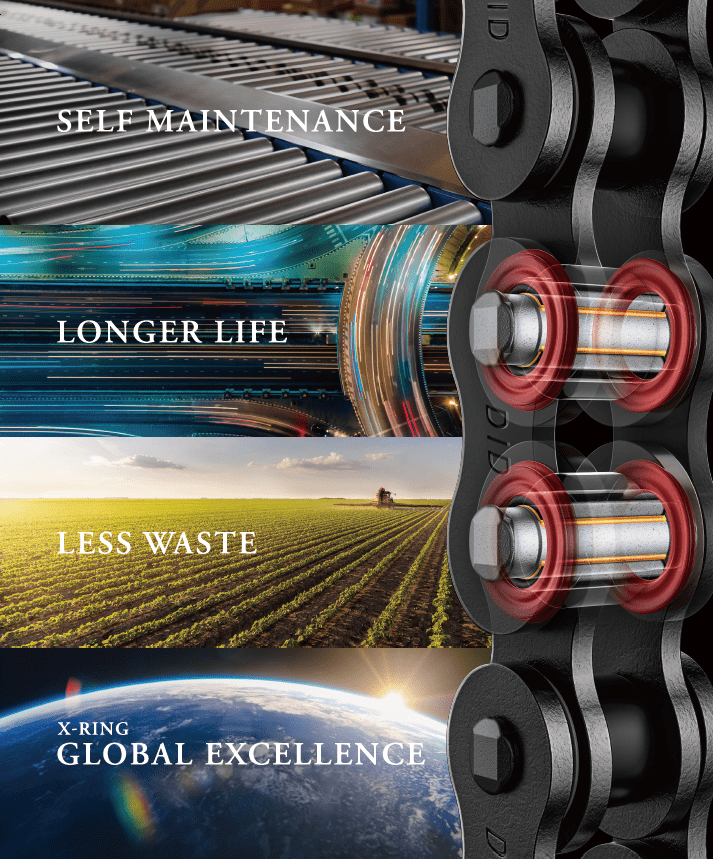

In today’s fast-paced industrial landscape, where precision, reliability, and uptime are paramount, the longevity of critical components like chains plays a key role in keeping operations running smoothly. For industries that rely on heavy-duty machinery, D.I.D ’s X-Ring/O-Ring chains stand out as the go-to solution for improving wear resistance, reducing maintenance costs, and extending service life in the toughest conditions.

D.I.D: Engineering Excellence with Japanese Precision

The D.I.D brand has a rich legacy of producing high-performance chains with Japanese engineering precision. While the brand is globally recognized for its motorcycle chains, it brings the same level of craftsmanship and cutting-edge technology to its industrial chains.

Since 2004, DID Europe has managed sales, logistics, and customer support across over 30 countries, delivering top-tier solutions to industries worldwide. Leveraging its extensive knowledge in the automotive and motorcycle sectors, D.I.D applies the same high standards to industrial applications, ensuring outstanding performance across a range of sectors, including automotive, manufacturing, energy, and material handling.

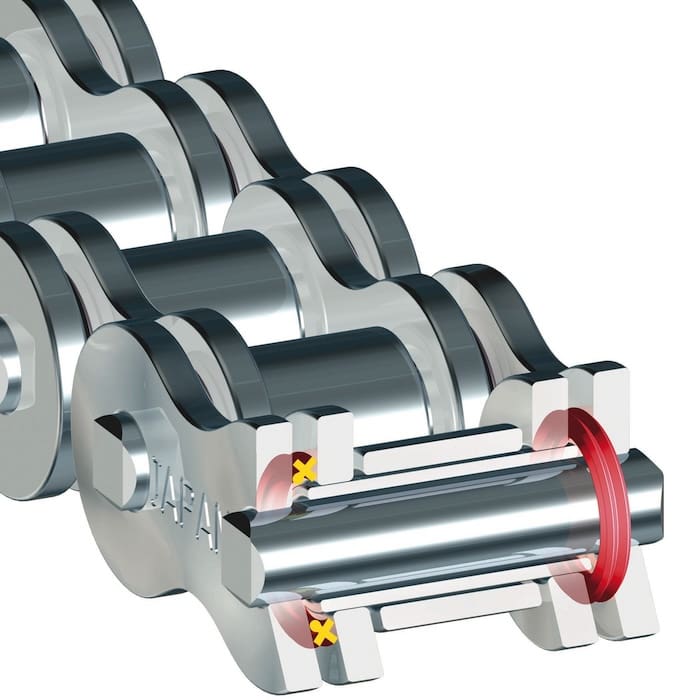

How D.I.D X-Ring/O-Ring Technology Redefines Chain Durability

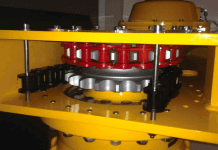

At the core of D.I.D’s innovative chains is their unique X-Ring/O-Ring technology, which fundamentally changes the way chains operate. The key to the extraordinary durability of X-Ring/O-Ring chains lies in the unique sealing mechanism. By encapsulating grease between the pins and bushings, these chains are protected from contaminants and excessive friction. Unlike standard roller chains, which are vulnerable to dirt, dust, and lack of lubrication, D.I.D’s X-Ring/O-Ring chains maintain superior lubrication, even in environments where maintenance is difficult or impractical.

This advanced sealing mechanism not only enhances wear resistance but also results in up to 12 times longer chain life when compared to standard roller chains. Over time, this reduction in wear translates to significantly lower operational and replacement costs, making these chains a cost-effective solution for industries that require high-performance, long-lasting components.

Key Benefits: Noise Reduction, Vibration Control, and Long-Term Efficiency

The benefits of D.I.D’s X-Ring/O-Ring chains extend beyond durability. With friction tests demonstrating that these chains require half the bending force compared to traditional O-Ring models, D.I.D chains outperform the competition in terms of smoothness, energy efficiency, and overall wear.

These chains also operate at a 3dB lower noise level than traditional roller chains, a significant difference in environments where noise reduction is a priority. Additionally, D.I.D chains generate less vibration than O-Ring chains, resulting in smoother operation and less stress on machinery, key factors for ensuring optimal system performance and longevity.

Recommended Applications for D.I.D’s X-Ring/O-Ring Chains

X-Ring/O-Ring chains are particularly suited for applications where:

- Lubrication is difficult: In industries where regular maintenance is challenging, the sealed grease offers a longer-lasting lubrication solution.

- Dirty and demanding environments: Applications in conditions with soil, sand, or dust benefit from the superior sealing and durability of X-Ring/O-Ring technology.

- Frequent chain replacement is costly: In industries where chains wear out quickly, D.I.D’s extended chain life reduces the need for frequent replacements, cutting down on downtime and labor costs.

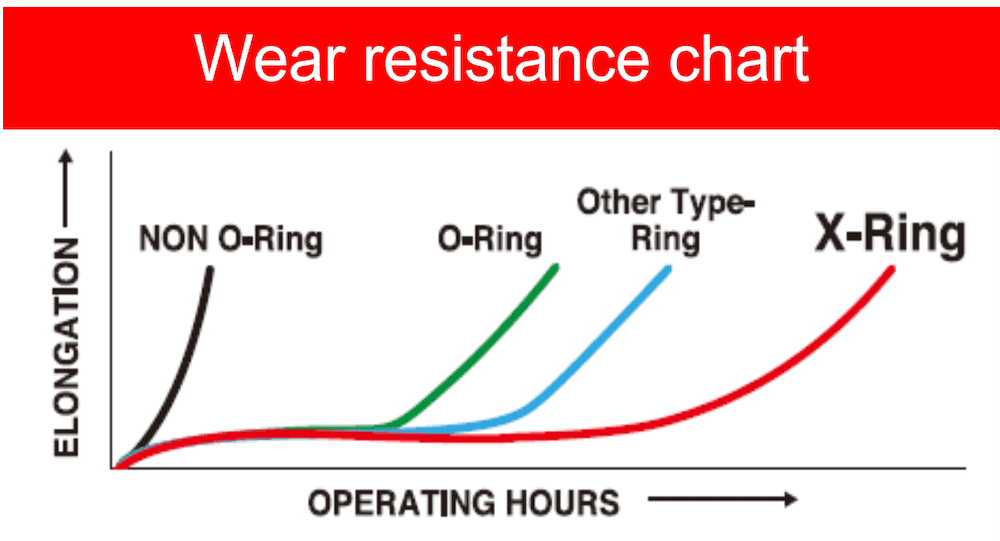

Performance Testing: X-Ring Chains Lead the Pack

D.I.D X-Ring technology excels in performance testing, consistently outperforming other non-sealed chains. The elongation curve comparison between standard roller chains and X-Ring chains shows a stark difference: while standard roller chains experience rapid elongation, D.I.D chains maintain their integrity and wear resistance much longer, with the blue curve illustrating significantly less elongation over time.

Global Reach, Local Expertise

At D.I.D, quality is the foundation of everything we do. Every chain we manufacture is designed with precision, ensuring seamless operation and high performance across diverse industries worldwide. Whether in Europe, Asia, or North America, D.I.D delivers the same premium level of reliability to our clients, backed by expert knowledge and support.

As global markets evolve, D.I.D continues to lead the way with next-generation solutions that empower smarter, more sustainable industrial operations.

Get to know D.I.D brand at EPTDA 2025

DID Europe will be showcasing its advanced industrial chain solutions at the EPTDA Annual Convention 2025, one of the leading events in the industry, gathering power transmission and motion control professionals from around the world.

This year’s theme, “Unleashing the Power of Our Network”, emphasizes the immense value of collaboration. At D.I.D, collaboration is key.

We pioneer advanced chain technologies through long-term partnerships with OEMs and Distribution-Partners, based on trust, responsibility, and shared success, meeting every challenge with technical expertise and unwavering commitment.

Book an appointment at our MDIDEX booth to explore how our precision-engineered chains can enhance your operations, increase efficiency, and minimize downtime. Our team will be available to discuss the latest innovations and demonstrate how D.I.D chains can move your business forward.

📍Location: Monte Carlo, Monaco (Fairmont Monte Carlo Hotel)

📅 Dates: 11–13th September 2025

For more detailed information on D.I.D’s X-Ring chain, explore the brochure here.

Choose D.I.D for a business where durability, performance, and precision engineering meet. Because when it comes to industrial chains, D.I.D is the name you can trust.