- 7 in 10 firms see stainless steel as vital for cutting Scope 3 emissions

- Life-cycle-cost analysis highlights its durability and scrap value

- Two-thirds plan higher use, led by infrastructure, mobility, and defense

Outokumpu, the global leader in sustainable stainless steel, has published a new whitepaper showing that 7 in 10 organizations view stainless steel as key for reducing Scope 3 emissions – and a more sustainable material than the alternatives.

The whitepaper, titled The Evolution of Materials – Stainless Steel Insights 2025, draws on insights from a global survey conducted for 70 senior decision-makers at companies with a combined annual revenue of ~428.85 billion USD (2024) – including some of the world’s biggest steel consumers across energy, consumer goods, automotive, construction and infrastructure*.

The whitepaper, titled The Evolution of Materials – Stainless Steel Insights 2025, draws on insights from a global survey conducted for 70 senior decision-makers at companies with a combined annual revenue of ~428.85 billion USD (2024) – including some of the world’s biggest steel consumers across energy, consumer goods, automotive, construction and infrastructure*.

The survey, which was conducted in May 2025, reveals that one in four organizations now name life-cycle-cost (LCC) as the principal reason to choose stainless steel, with almost half (40%) saying they now run LCC analyses. Price is still a key factor in material selection, but use of methodologies that factor in longer-term value is growing, especially in Europe.

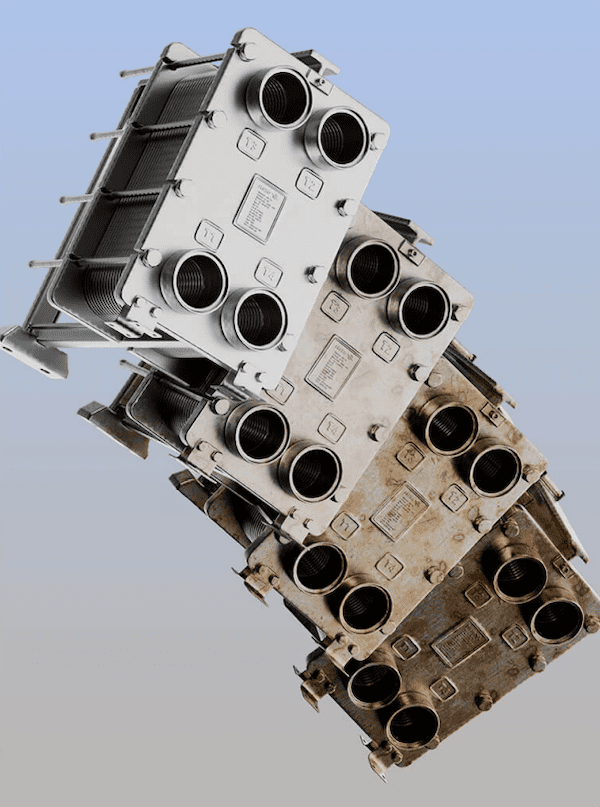

LCC is becoming increasingly important as organizations seek to reduce not just financial outlay but also environmental impact. Corrosion, for example, is a major contributor to long-term maintenance and replacement costs across sectors. Globally, corrosion-related losses are estimated to exceed $2.5 trillion annually, with significant climate implications due to the need to replace degraded materials. Factoring these costs into planning through LCC analysis helps organizations make smarter, more sustainable choices – often revealing stainless steel as the more competitive option over time.

LCC is becoming increasingly important as organizations seek to reduce not just financial outlay but also environmental impact. Corrosion, for example, is a major contributor to long-term maintenance and replacement costs across sectors. Globally, corrosion-related losses are estimated to exceed $2.5 trillion annually, with significant climate implications due to the need to replace degraded materials. Factoring these costs into planning through LCC analysis helps organizations make smarter, more sustainable choices – often revealing stainless steel as the more competitive option over time.

Nearly 60% of respondents believe that stainless steel now offers better overall value than substitutes and well over half say that its high scrap value contributes to offsetting higher upfront cost.

“The move toward life-cycle-cost analysis signals a broader shift in how organizations assess material value. While stainless steel may sometimes have a higher upfront cost, its longevity and low associated maintenance often make it a smarter long-term investment. Organizations also increasingly recognise its role in reducing Scope 3 emissions and  supporting sustainable operation. As a result, the metal is being adopted more widely – and across new sectors, serving as a cornerstone of the circular economy”, says Britta Warnke, VP Commercial at Outokumpu.

supporting sustainable operation. As a result, the metal is being adopted more widely – and across new sectors, serving as a cornerstone of the circular economy”, says Britta Warnke, VP Commercial at Outokumpu.

Stainless steel’s role continues to expand beyond traditional niche industries

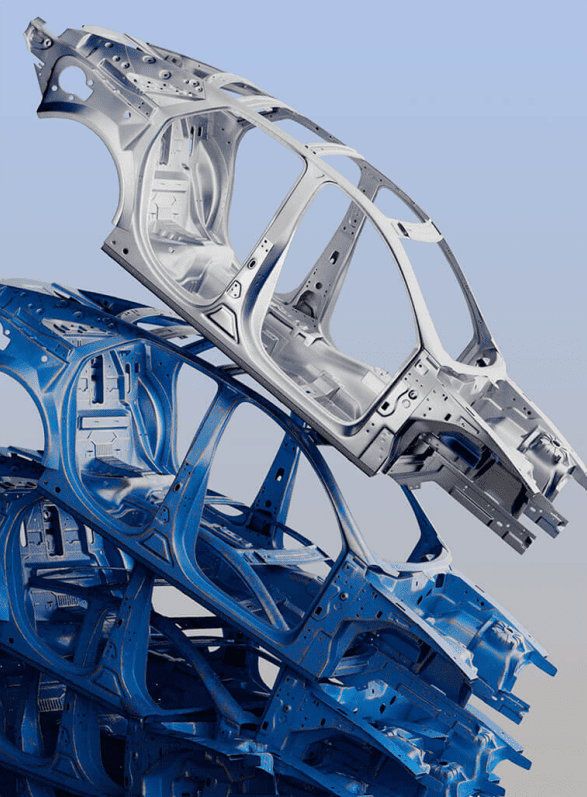

Combining durability, corrosion resistance, strength and recyclability, stainless steel is uniquely positioned to meet the materials challenge facing a world impacted by climate change, rapid population growth and tighter environmental regulation. Its use is expanding, with new applications seen in several spheres – from EV battery boxes, hydrogen plants and solar farms, to urban flood defenses, port infrastructure, defense systems, and even next‑generation space technology.

In line with this, the research also reveals strong momentum in demand, with two-thirds of respondents expecting to increase stainless steel intake over the next five years.

The mid-to-long-term demand surge is driven by stainless steel’s expanding role beyond traditional niche industries. More extreme temperatures, flooding and other weather events are placing infrastructure under unprecedented strain, making stainless steel’s corrosion resistance and strength more valuable than ever – from use for bridges and coastal defenses to tunnels and skyscrapers. Its recyclability and long-life cycle reinforce its role in building resilient, low-impact infrastructure.

The mid-to-long-term demand surge is driven by stainless steel’s expanding role beyond traditional niche industries. More extreme temperatures, flooding and other weather events are placing infrastructure under unprecedented strain, making stainless steel’s corrosion resistance and strength more valuable than ever – from use for bridges and coastal defenses to tunnels and skyscrapers. Its recyclability and long-life cycle reinforce its role in building resilient, low-impact infrastructure.

The metal is also gaining prominence in defense and aerospace, as security concerns drive military investment. The EU’s €800 billion ReArm Europe plan, which prioritizes resilience and sustainable materials, is set to boost demand for advanced stainless grades that extend asset lifespans and support the shift to low-carbon military infrastructure. From reusable rockets to energy-efficient surveillance systems, stainless steel is proving essential where durability, heat resistance and circularity are critical. At the same time, electric vehicle manufacturers are increasing stainless steel use to enhance fire safety in operation – further cementing its role in the future of mobility.

*) The survey included single-choice, open-ended, and Likert-scale items. Quantitative and qualitative data were collected and analyzed by Kairos Future, yielding 49 completed responses (70% response rate). Geographically, respondents break down into Europe (41%), United States (24%) and those operating globally (35%) – a mix that provides a reasonably balanced view of regional priorities and pain-points.

The full whitepaper, The Evolution of Materials: Stainless Steel Insights 2025, is available to read here.