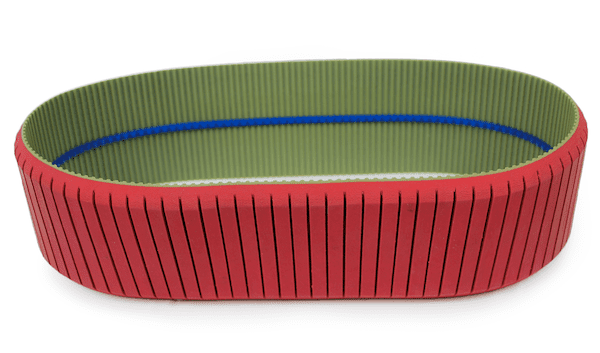

Packaging and labelling equipment benefits from belts engineered for accuracy and dependable running. Ydins supplies custom-made belts, combining specific machining, coatings and finishes to address the distinct steps in these processes.

Engineered adaptations for perfect fit

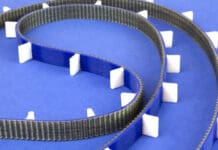

Many machines operate with small pulley diameters. In such cases, custom machining ensures the belt conforms to tight radii without sacrificing efficiency. Cross-cut top layers aid operation on small pulleys while maintaining rotational resistance.

On the toothed base, further machining is possible — such as adding internal guides or reducing tooth height — to stabilize product handling and minimize line deviations.

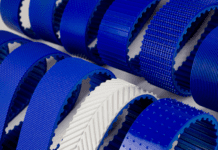

Multi-coating configurations

Ydins can specify multiple coatings on a single belt. A softer, under-padded material cushions delicate products, while a harder, non-slip outer layer secures grip.

Coatings are available in various hardness levels and surface finishes to meet environmental demands, from abrasion resistance to precise friction control.

Compliance for food and pharma contact

For direct contact with food or pharmaceutical products, Ydins offers timing belts and coatings made from fully FDA-certified materials to support hygienic and compliant processing.

Customised technical support

Each project begins with individual assessment: machine geometry, operating conditions and product characteristics are reviewed to select and design the most suitable belt. The objective is consistent performance, long service life and high reliability.

Looking for a belt adapted to your packaging line?

Get in touch with Ydins’ technical team to develop the right solution.

🌍 www.ydins.es | ✉ [email protected]