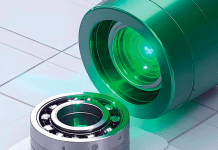

Artificial intelligence is rapidly reshaping how bearings and components are manufactured, inspected, and delivered to market. During his presentation titled “Transforming Bearing & Components Manufacturing with AI-Driven Optical Inspection” at the Bearing & Power Transmission World Meetings 2025, Sean Fang of K2TECH highlighted how AI and machine vision are redefining quality assurance and efficiency across production lines.

Today’s bearing manufacturers face three key challenges: rising labour costs, maintaining consistent quality, and improving overall equipment effectiveness (OEE). Bearings operate in nearly every industrial sector, where even minor defects can cause costly downtime. Traditional visual inspection methods, dependent on manual judgment and fixed algorithms, often struggle with irregular defects or inconsistent lighting.

AI-driven optical inspection offers a solution. By combining AI “intelligence” as the brain, machine vision as the eyes, and robotic automation as the hands, manufacturers can create a fully integrated inspection ecosystem. This synergy delivers tangible performance gains, accuracy within 0.1 mm, overkill rates below 1 %, and OEE improvements exceeding 8 %. Each production line can also save the equivalent of four full-time operators.

Through deep-learning algorithms, AI systems can distinguish between true defects and harmless variations such as dark spots from heat treatment or oil films, reducing false detections by up to tenfold. New defect types can be configured in minutes, shortening adjustment times from weeks to hours. The result is greater flexibility, faster response, and more stable inspection performance, even under variable lighting or surface conditions.

The next phase in this evolution is centralized AI learning. Using cloud connectivity, production data from multiple lines can be uploaded, analysed, and used to train a unified inspection model. Once optimized, this model can be deployed across all machines — enabling real-time quality monitoring and continuous improvement in line with Industry 4.0 principles.

AI-driven optical inspection is no longer experimental; it is becoming a cornerstone of smart, data-driven bearing manufacturing, ensuring consistent quality, lower costs, and a more intelligent future for the industry.

Join the conversation shaping this transformation at the Bearing & Power Transmission Forum 2026, where global experts, manufacturers and distributors will gather to discuss the technologies defining the future of our industry. Visit www.bearing-power.com for more details.