The Story of SKF’s Microlog dBX

In high-risk industrial environments, safety-certified equipment is essential for preventing fires, explosions, and operational disruptions. To address the needs of customers working in oil & gas, petrochemical, biofuel, and other hazardous-area industries, SKF has introduced a hazardous-area approved version of its flagship Microlog Analyzer dBX. In this interview, Sam Bainbridge, Director of Technology Delivery, North America at SKF, explains what led to the development of the new device, how it was engineered, and what it means for customers advancing their condition monitoring strategies.

What specific customer challenges or requests led SKF to develop a hazardous-area certified version of the Microlog Analyzer dBX?

Some of the biggest users of handheld data collectors require hazardous area certification to prevent fires, explosions, and catastrophic accidents. These users operate in sectors including Oil & Gas, Petrochemical, Biofuel, Wastewater treatment, and some mining applications. Without hazardous area certification, it’s not possible to safely operate in these environments. SKF is continuously striving to expand its condition monitoring offering and bring new value to customers and industries. This led to the development of a hazardous area-approved Microlog Analyzer dBX model CMVA 90-EX that is approved for use in ATEX, IECEx, Class I Division 2 and Class I Zone 2 rated areas.

How does this new version of the Microlog Analyzer dBX differ technically from the standard version?

The Microlog Analyzer dBX is SKF’s most advanced portable vibration monitoring device. The hazardous area-approved version is almost identical from a technical features and capabilities perspective to the standard version. However, it has been designed to enable safe operation of electrical equipment in hazardous areas by limiting the amount of stored and transmitted electrical energy to prevent sparks or high temperatures that could ignite gases. In addition, the SKF Microlog dBX CMVA 90-EX kit includes hand and neck straps that are specifically designed for hazardous environments as well as a hazardous environment rated general purpose accelerometer, cable and magnet mount. With any hazardous area device, there are important considerations for use.

Could you walk us through the certification process (IECEx, ATEX, Class I Division 2, Class I Zone 2) and why these standards are crucial for your customers?

The device manufacturer and any 3rd party partners must go through a rigorous – and sometimes long and complicated – process to qualify both the device and manufacturing facilities. It’s not uncommon for a certification to take 12 months or longer. After a manufacturer has satisfied all requirements, they are issued a certification and must include proper marks on the product meeting the requirement. These standards are crucial to ensure that our products can withstand the working conditions of our customers’ facilities while delivering optimal performance.

What were the biggest engineering challenges in designing a device that balances highperformance vibration analysis with safety in hazardous environments?

Design engineers must integrate sensitive, high-speed data acquisition hardware capable of capturing precise vibration signatures while ensuring the device meets hazardous area design standards. This balance demands careful component selection, thermal management, and power efficiency to prevent ignition risks without compromising analytical accuracy or processing speed. Additionally, maintaining usability – such as long battery life, rugged housing, and intuitive interfaces – under harsh environmental conditions adds further complexity to achieving a reliable, highperformance, and safety-compliant instrument.

How does the device specifically support customers in industries like oil & gas, chemical processing, or food & beverage (ethanol)?

Operations in these industries usually have hazardous classified areas. In most cases, these are ATEX or IECEx Class I Zone 2, or NEC 500 Class I Division 2 rated areas where there is low probability of an explosive atmosphere in the form of gas or vapor being present during normal operation but if it does occur, it will only persist for a short period.

How does this device integrate into broader plantwide condition monitoring systems and digital transformation initiatives?

The SKF Microlog Analyzer dBX is part of our plantwide condition monitoring solutions, including portable, wireless, online and protection systems as well as on-premises and cloud-based analytics software. Machine alarms and SKF diagnostic reports are displayed on modern and interactive dashboards. Such tools help maintenance and reliability teams focus their attention where it’s needed and fix problems before they lead to unplanned downtime. In addition, we offer various data integration solutions ranging from widely used protocols such as Modbus and OPC UA to web APIs such as SKF Phoenix API to more advanced data pipeline capabilities. SKF solutions are customized to address customers’ needs, making vibration data readily available to integrate with the customer’s CMMS (Computerized Maintenance Management Systems), data historians (such as Aveva PI) or other, supporting our customers’ digital transformation initiatives.

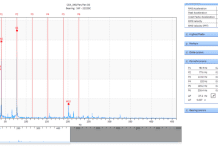

The new model claims “MPA-in-a-flash” data acquisition three times faster than earlier models. What does this mean for users in practice?

MPA stands for Multiple Point Automation. This is one of the key improvements with the Microlog dBX platform as compared to legacy CMXA series Micrologs. The Microlog dBX platform offers more advanced computing capabilities, enabling the user to configure up to 12 measurements for automatic data collection at one measurement point. Using the same sensor, the user needs to press only one button to collect all pre-configured MPA measurements. As a result, field experience has shown up to three times faster data collection. For SKF customers, this means less time collecting data and more time troubleshooting and resolving issues.

How does the built-in camera enhance the operator’s ability to perform diagnostics and documentation in hazardous areas?

The built-in camera enables quick, visual confirmation of equipment condition and sensor placement without the need for a separate hazardous approved camera. It allows the operator to capture images of machinery and environmental factors during data collection, providing valuable context to vibration readings. This visual documentation improves diagnostic accuracy, supports remote analysis, and streamlines reporting while reducing time spent in potentially dangerous locations, thereby increasing both safety and efficiency in field operations.

Could you elaborate on the advanced analysis functions, such as SKF gE bearing analysis, and why these are important for reliability engineers?

In addition to route-based data collection, the SKF Microlog Analyzer dBX offers up to 10 advanced on-device data analysis apps, including Balancing, Orbit Analysis, FRF & ODS Analysis and gE Enveloping, to name a few. These apps offer pre-set templates built with the typical parameters required to perform specific types of testing. For example, the gE Enveloping app helps reliability engineers determine the condition of rolling element bearings more efficiently.

How does this product strengthen SKF’s condition monitoring portfolio in North America compared to global markets?

The United States and Canada account for one of the largest shares of oil and gas production globally. The scale of operations is massive, which plays a significant contribution to total demand for handheld vibration data collectors. SKF Microlog dBX CMVA 90-EX is the class leader in this space, so we expect it to play a crucial role in our product portfolio.

With digitalization accelerating, how do you see portable tools like the Microlog Analyzer dBX fitting alongside online monitoring systems and AI-driven analytics?

It’s an interesting question. We’ve seen increasing adoption of continuous monitoring solutions such as SKF IMx-1 wireless system and IMx8/16 online systems, helping customers on their digital transformation journey. At SKF, we take a wholistic approach when solving customer challenges, often using a combination of technologies including continuous and handheld data collection. In particular, the Microlog dBX is crucial in fault detection confirmation and advanced troubleshooting techniques. And product demand backs that up – we have seen tremendous adoption of our latest handheld data collectors.

Regarding AI-driven analytics, we take a hybrid approach. We use AI/ML tools behind the scenes to improve our efficiency, but every notification and machine health report provided to a customer is verified by a human analyst. Our experience is that the error rate of AI/ML tools is still not to the levels we expect in our service offer and, crucially, a lone vibration algorithm cannot account for context on and around an asset like a human can.

What kind of ROI can customers expect when deploying this device compared to traditional maintenance methods?

Catastrophic failure of a critical machine in an industry such as Oil and Gas can lead to significant financial losses because of production loss, environmental and safety implications and expensive repair. If one fault can be detected, avoiding unplanned machine downtime and supporting a proactive approach to maintenance, the detection equipment (i.e., the Microlog dBX) has paid for itself. It’s not uncommon to see payback periods in a matter of months. These tools help customers get ahead of that curve, anticipating machine failure before it happens. With high quality data, they can properly plan maintenance events.

Looking ahead, how does this launch fit into SKF’s broader vision for predictive maintenance and reliability in hazardous and non-hazardous environments?

SKF is committed to continuing to invest in the development and enhancement of its portfolio of condition monitoring technology and solutions. Hazardous area capability is a cornerstone to that strategy. We are positioned to be the leader in this space with exciting developments on the horizon and much more to come in 2026.

This article is published in Motion+Drives December 2025 issue on pages 42-45