The trend towards individualized products and the increasing demand for a greater variety of variants require a mindset change in production engineering. Companies that meet this demand can gain competitive advantages. However, the products provided by these companies often have to compete with competitive products from highly efficient automated and rigid production. The challenge is to economically and competitively produce smaller quantities of highly individualized products. Suitable production systems, which are characterized equally by high flexibility and a high degree of automation, do not exist or have been existing only in rudimentary form so far. The researchers at KIT want to close this gap: The value stream kinematic system they currently develop in close cooperation with their industrial partners GROB-Werke and Siemens is a production system that combines the high productivity and precision of special machines with the flexibility and versatility of industrial robots.

One Kinematic System for All Processes

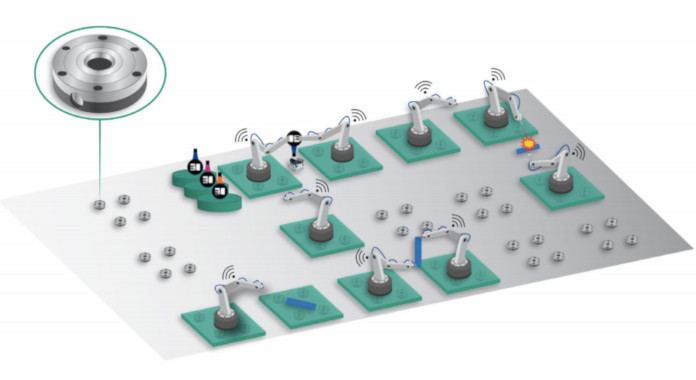

This innovative production system focuses on mapping entire production flows using uniform standard kinematic systems based on vertical articulated-arm robots. In addition to the usual robotics handling tasks, the standard unit also carries out diverse other processes, such as assembly, 3D printing, cutting and joining, and machining. Standard kinematic production set-ups allow frequent and flexible rearrangements of the production system without the need to purchase additional equipment. The simple and quick change of a production layout is supported by a grid of zero-point clamping systems. This grid extends over the entire production area and allows the standard kinematic systems to be quickly repositioned at the specified clamping points.

Cooperating Kinematic Systems

In order for the kinematic system to be able to carry out demanding processes such as machining tasks, various optimization measures are required compared to conventional industrial robots, e.g., the use of innovative gear technologies and the software-based compensation of path deviations. A further optimization measure is the coupling of kinematic systems using human-operator approaches as a model: Demanding tasks with high forces, heavy loads, or poor manageability can be mastered with support from other persons. According to this principle, several kinematics can solve a challenging task together. The degree of support can range from the joint handling of an object to the mechanical coupling of kinematic systems.

Engineering Platform

A further aspect of value stream kinematics is the software-side support of the hardware. The set-up and constant rearrangement of a production system are complex and time-consuming processes. A comprehensive engineering platform supports the production engineers in this process and significantly reduces the production system’s planning and commissioning time. The engineering platform is intended to provide the engineers with holistic support, from the creation of a product in CAD, to planning the number and arrangement of the kinematic units, through to the final simulation of the production system.