BANDO is a 115-year-old multinational enterprise based in KOBE, Japan. The company’s main products are transmission belts for various kind of industries, automotive, motorcycle engine parts and industrial machines, HVAC, factory related parts/elevators, bank machines, security cameras in the town and printers or photo copiers in your office or in your house.

BANDO EUROPE has been established in 1978 – since then the company supplied transmission belts to Europe’s competitive manufacturers mainly in automotive industries and precision machinery industries. The new challenge is to contribute to solving Europe’s advanced and world’s most required issues which is to reduce carbon emission and save energy.

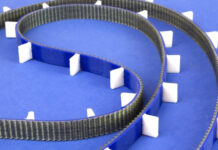

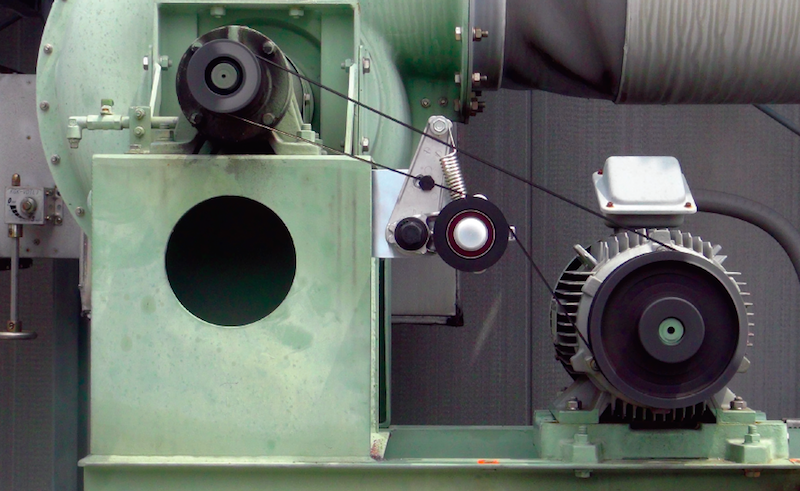

BANDO introduced the energy saving transmission belt system called “HFD” which stands for Hyper Flat belt Drive, since the BANDO’s engineering team believes that the combination of “FLAT BELT” + “AUTO TENSIONER” is the most efficient transmission belt system for HVAC industry. More than 100,000 units of blowers and 130,000 units of cooling towers with conventional V-belts are running in Japan. It is estimated that – a possible change of those 230,000 units V-belts into HFD systems – could reduce approximately 60 GWh, which is almost equivalent to the electricity generated by one small size coal fired power plant.

BANDO has released around 7,000 units of HFDs in Japan, China, Korea and Taiwan. On the other hand, in Europe with the world’s most advanced area for environmental protection, the company did not promote this advanced technology yet and aims to be the evangelist who will preach around the method how specific applications can reduce 5~7% of energy consumption with transmission belt systems.

HFD has two other features: One of them is the longer lifetime, HFD can achieve 24,000 hours lifetime, while a conventional v-belt’s lifetime is around 8000 hours. The second feature is the maintenance-free solution. These days workforce for facility and asset maintenance has been reduced because of declining working population. For a conventional v-belt, three to four times maintenance is required during its 8000 hours lifetime. But HFD doesn’t require any maintenance for its 24,000 hours lifetime and contributes to solve several related socio-economic problems.

How can BANDO achieve these major strong features? This is thanks to the patented tensioner pulley and the development process of the belt materials. For cars with an engine, the company offers a transmission belt maintenance solution for over 50,000 km. This thanks to the accessory drive produced for automotive engines; a ribbed belt and auto tensioner which enables the long life and long-term maintenance-free operation. BANDO introduced this advanced technology from the automotive industry into industrial applications. A good example is the comparison of a conventional v-belt and a flat belt. A flat belt is easy to bend, which means an easy installation capability on pulleys. A conventional v-belt needs more energy to be installed on pulleys, which causes the major loss for belt transmission.

BANDO also introduced a flat surface belt and the meander correction pulley. For the high-power motor application, it was not possible to use ribbed belts that have tiny V shape ribs on the surface, because they got destroyed with higher engine power. The company decided therefore to use flat surface belts instead. However, flat belts cannot run straight without any guide or flange. So, the introduction of the “meander correction pulley” which enables belts to run straight was the solution. With these technologies and innovations, BANDO could achieve “Energy Saving”, “Long Life” and “Maintenance-Free” operations.

BANDO is looking for the right business partners from the following areas to build a long-terms cooperation.

1. OEM supply for HVAC (blowers, compressors)

2. Maintenance operation professional companies with wide network, especially for HVAC system. (Public facilities, Hospitals, Shopping Malls, and Factory)

3. Major manufacturing companies who have a target or goals for environmental protection or carbon offset.

Feel free to contact [email protected] in case you are interested in a partnership with BANDO.

This article is published in MOTION+DRIVES Oct-Nov-Dec 2021 issue.

Download the .pdf version or Read the eMagazine