When talking about manufacturing, various methods can be grouped into the three big families of methods: Subtractive manufacturing (e.g. machining), formative (e.g. molding) and finally additive manufacturing: this last one involves adding material in layers, in order to create the final product.

Some of the main benefits of additive, especially when compared to subtractive and formative manufacturing, can be:

- Customization: components can be highly customized in an economically viable way and with low turnaround times.

- New and complex designs & flexibility: The potential to create complex structures without impact on the cost to manufacture is a trademark benefit of 3D printing. Without the limitations injection molding or CNC machining, users are able to create intricate designs that do not depend on tooling suppliers or MOQ

- Cost and time savings: as mentioned, though elimination of molds, additional equipment and tools that are both expensive and require some lead-times to be manufactured and delivered. Also, any design change can be done almost in a click and the new edited batch of parts can be good to go in days or a week, instead of weeks or months.

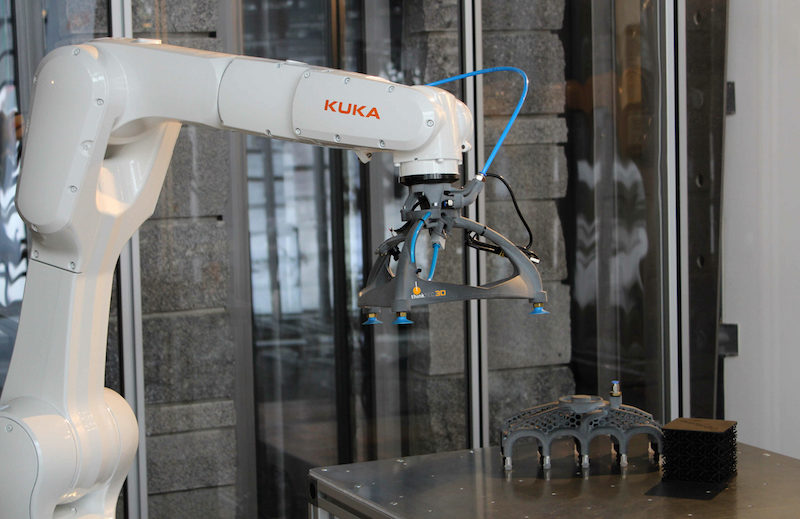

Obviously, even among different 3D Printer providers, the selection of the right technology is one the main drivers for success: in order to manufacture very large parts, like end-of-arm-tooling or big jigs and fixtures, the technology with the sufficient capacity must be seeked out. And a similar consideration must be done regarding very small parts that need very high dimensional accuracy, like small needle bearing cages, where the margin of error must be minimum. Not all technologies will be up to the task!

If the focus is on final parts with a need for high quality and precision, or components that will be used consistently, a powder bed technology might work better, because it allows lower margins of error, and most importantly flexibility in terms of productivity.

That is because powder bed technologies allow as many parts as can fit on the same surface to be placed into the building area, and the print job (per layer) will take the same time as only printing one. Moreover, parts can be stacked one over the other inside the build unit and the user can control at what distance, monitoring heat and temperature, everything can be set based on specific requirements or needs. Finally, managing to stack parts without filling the unit to the top will reduce the hours needed to print the job.

What most of HP 3D Printing’s users do after installing the technology in their facilities, is to look at parts which were designed for CNC Machining or Inject Moulding and try to switch those designs to 3D. But, of course, parts designed for traditional manufacturing technologies will have shapes and properties that are different from what one would come up with if it were to directly design a part for additive. So, at that point, parts’ designs are normally made hollow, or lattice structures are introduced, which are both very effective methods in reducing material usage and, consequentially, weight of the parts as well as the cost.

But as users get more comfortable with 3D printing technologies, what happens is a more intricate approach towards design. A typical upgrade from traditional design to additive is part consolidation: when an assembly of parts is re-designed in a single component, which allows savings in terms of assembly times and costs for the tooling, and is a very effective way to reduce the risk of liquid or air leakage. Any junction from a component that is supposed to be fluid tight can be dangerous for the performance of the part: by transitioning to one component this is obviously not a concern anymore.

And as they become experts in the technology that they use, parts start being directly and specifically designed for 3D. Not adapted, but re-imagined starting from design to final series production.

But 3D Printing does not stop at the end of the printing phase: to complete the manufacturing process, there are several post-processing options. When considering HP Multi Jet Fusion Technology, parts that come out of the printer need to be cleaned through sand blasting or any option that will remove the excess unused powder still attached to them, reaching a clean, rough-surfaced, grey part. Then, depending on requirements, there are different options:

- Enhancing scratch and colour resistance for frequently handled parts through dying and graphite blasting;

- Applying a gloss finishing through the technology of chemical polishing;

- Customizing with any graphical pattern that will not shrink, will be weatherproof and will eliminate cutting edges through the process of hydrographics;

- Protecting parts against corrosion, improving electrical conductivity, reducing friction or preparing a surface for better paint adhesion with electroplating.

And many more.

In conclusion, when talking about 3D Printing and additive manufacturing, it is important to mention how this method is only extremely powerful when paired up with the right material, the right technology and the right partnership; nevertheless, its objective isn’t to replace other technologies outright, but to complement the traditional processes and is going to change the way that we produce. Therefore, it is crucial to be aware of the different additive technologies on the market and become familiar enough with them to actually take advantage of the benefits they enable.