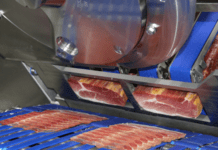

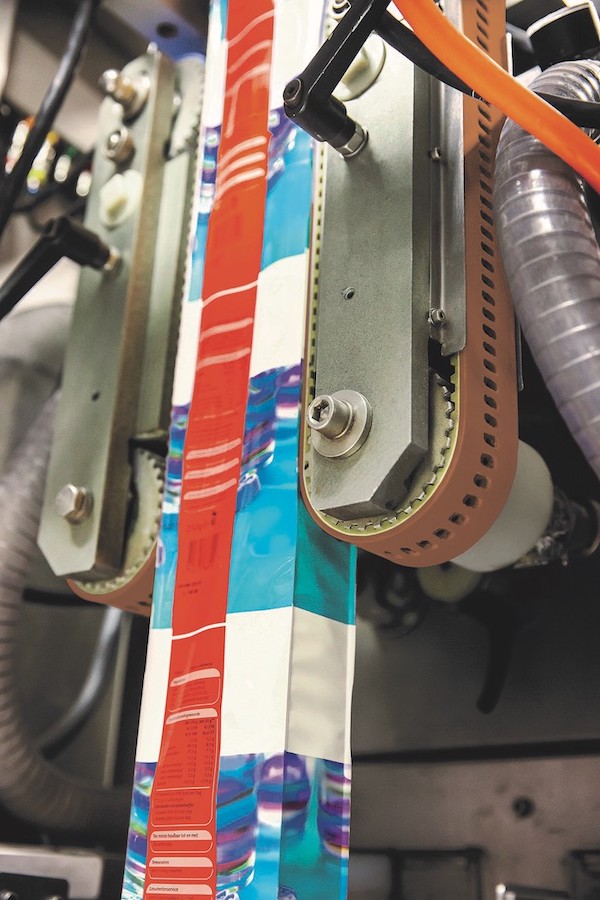

In the packaging industry, Vertical Form Fill Seal (VFFS) machines are essential for operational efficiency. These systems automate the entire process, transforming plastic sheeting into bags, filling them with products, and sealing them seamlessly in a continuous assembly line. As a result, VFFS equipment plays a vital role in sustaining high productivity and meeting industry demands.

However, various factors, such as bag material and environmental conditions, can pose significant challenges that necessitate customised solutions, including alternative cover materials. These adjustments are essential for ensuring optimal and consistent performance across packaging operations.

The customer’s challenge

One prominent customer faced a significant issue: loss of friction during the packaging process.

This problem was caused by the glazing of the coating material, which reduced grip and led to slippage during the forming phase. Additionally, the coating’s inadequate durability and low wear resistance exacerbated the problem, leading to heightened downtime and production delays, further impacting overall efficiency and contributing to disruptions in the packaging workflow.

This problem was caused by the glazing of the coating material, which reduced grip and led to slippage during the forming phase. Additionally, the coating’s inadequate durability and low wear resistance exacerbated the problem, leading to heightened downtime and production delays, further impacting overall efficiency and contributing to disruptions in the packaging workflow.

For packaging professionals, identifying and addressing the root causes of such issues is essential. It’s not merely about resolving immediate issues; it’s also about preventing future disruptions and enhancing operational reliability.

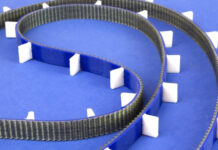

Megadyne customised solution

To solve friction loss effectively, Megadyne implemented a cutting-edge solution that transformed the customer’s operations.

By introducing a specialty belt with advanced cover material, Megadyne was able to deliver consistent friction and improved grip across various film types. This innovative approach resulted in a lifespan of three times longer than the customer’s previous solution, significantly enhancing overall efficiency.

Explore Megadyne case study

To delve deeper into these effective strategies and uncover valuable insights, explore the full Megadyne case study. For tailored solutions designed to meet specific packaging challenges, contact Megadyne experts.