As warehouse space becomes increasingly constrained, the pressure to optimise storage and retrieval systems grows. The challenge lies in storing more goods without sacrificing retrieval speed or accuracy.

When space-saving measures compromise performance, efficiency often suffers.

That’s why industry leaders are now adopting smarter, quieter solutions that not only maximise space but also elevate operational performance.

Case Study: defining the future of Vertical Lift Modules

Case Study: defining the future of Vertical Lift Modules

A recent project aimed at designing a next-generation vertical warehouse system that would achieve up to 90% space reduction while maintaining the same storage capacity. Key goals included reducing energy consumption and enhancing the speed and reliability of goods retrieval.

The customer’s previous system, based on chain drives for moving shelves, posed several challenges:

- High noise levels during operation

- Constant lubrication

- Lack of precision in movement

- Limited operational speeds

- Frequent downtime due to maintenance needs

These issues not only reduced the system’s uptime but also created inefficiencies and noise within the warehouse environment.

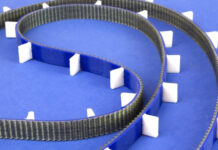

Megadyne’ solution: QST (Quiet, Self-Tracking) System

Megadyne’s QST System was the ideal solution. Unlike traditional chain drives or standard straight-tooth profiles, the QST system delivers a quieter, more reliable, and space-optimised alternative.

Want to see the full transformation? Download the full case study.