When strength, reliability, and endurance are nonnegotiable, D.I.D Ultimate Power Chains rise to the challenge.

When strength, reliability, and endurance are nonnegotiable, D.I.D Ultimate Power Chains rise to the challenge.

As part of the world-renowned D.I.D EUROPE portfolio,these chains are engineered to deliver superior fatigue strength, impact resistance, and transmission efficiency across a wide range of industrial applications.

As the European hub of DAIDO KOGYO, D.I.D. EUROPE ensures the seamless availability and support of D.I.D products across Europe, maintaining the exceptional quality that the brand is renowned for.

When strength, reliability, and endurance are nonnegotiable, D.I.D Ultimate Power Chains rise to the challenge. As part of the world-renowned D.I.D EUROPE portfolio, these chains are engineered to deliver superior fatigue strength, impact resistance, and transmission efficiency across a wide range of industrial applications.

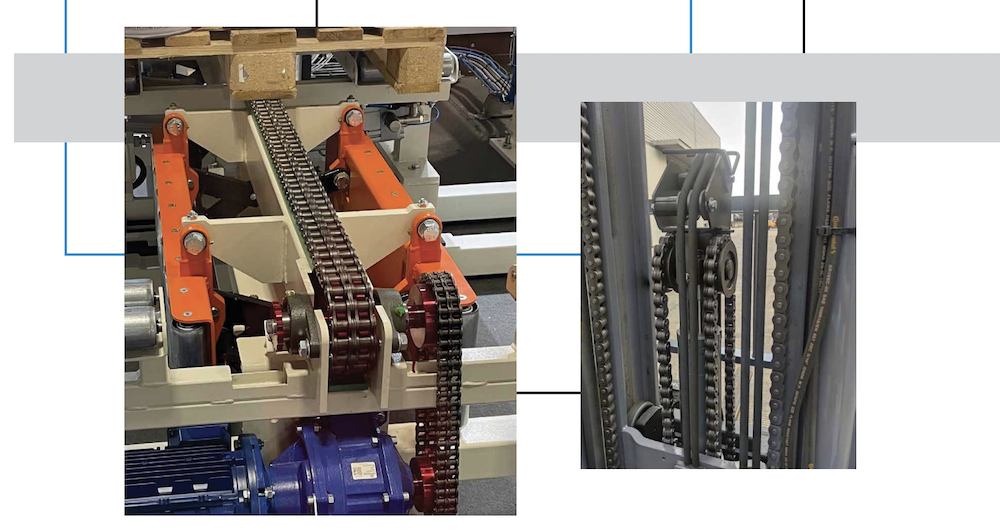

HI-PWR-S Ultimate Power Chains

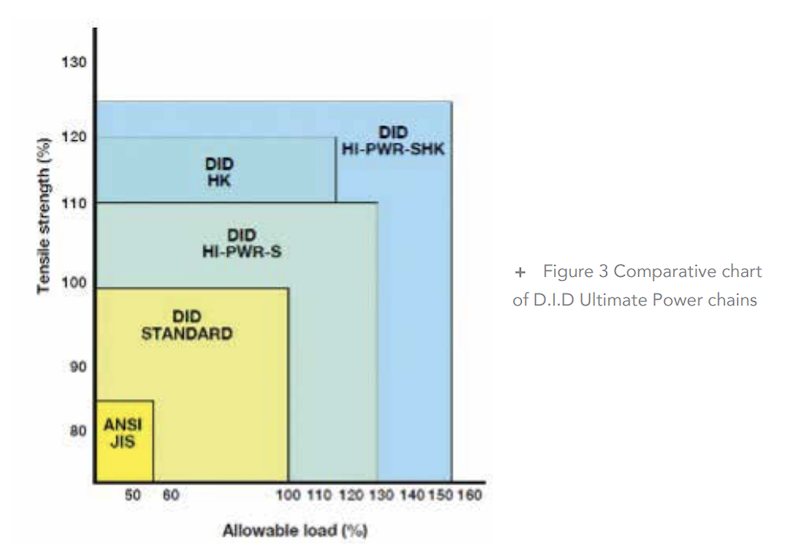

The D.I.D HI-PWR-S roller chains are designed to provide enhanced fatigue strength and impact resistance, all without altering the standard dimensions in the pin length direction. These chains maintain full compatibility with existing systems that adhere to ANSI/JIS Standard Roller Chains, while delivering upgraded performance in demanding environments.

The HI-PWR-S chains feature Oval Figured Wider Waist Link Plates and Thru Hardened Pins, offering exceptional resilience against wear and fatigue. Available in sizes 80 through 240 and with up to 3 strands in both riveted and cottered styles, these chains are built for versatility and extreme reliability.

Some of the key features include:

+ Enlarged plates for greater durability against dynamic and impact loads;

+ Higher machining and assembling accuracy for smoother, more efficient operation;

+ High transmission efficiency, making them ideal for applications across a wide range of speeds, from low to high;

+ Approximately 30% higher maximum kilowatt rating compared to standard roller chains in the medium to low-speed range.

Recommended Applications:

Thanks to their robust structure, the HI-PWR-S chains excel in environments with large shock loads, frequent start/stops, and high-speed operations. These include civil engineering machinery such as skid steers, trenchers, trucks, cranes, agitating trucks, forklifts, and drive units for conveyors, elevators, and stackers.

HK Chains: Superior Strength for Heavy-Duty Applications

HK type roller chains conform to the H type of ANSI standards, and their inner and outer link plate thicknesses are equivalent to those of the next larger size chain. As a result, HK type roller chains offer a significant improvement in performance, with a tensile strength approximately 20% higher and a maximum allowable load about 15% greater than that of standard roller chains. While their weight has also increased, these chains are ideal for heavy-duty applications operating at low speeds.

HK type roller chains are optimal for applications requiring higher strength, where the use of larger and heavier chains would be impractical. A prime example of such applications is asphalt finishers, where the need for enhanced durability and performance under demanding conditions is critical.

HK type roller chains are optimal for applications requiring higher strength, where the use of larger and heavier chains would be impractical. A prime example of such applications is asphalt finishers, where the need for enhanced durability and performance under demanding conditions is critical.

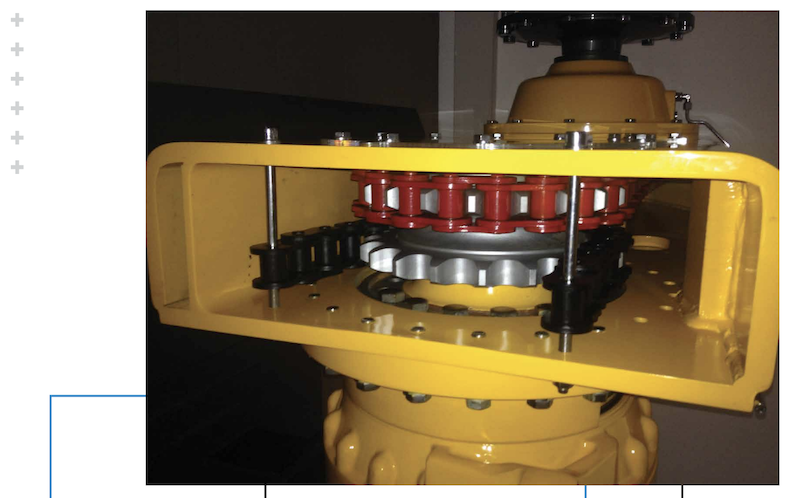

HI-PWR-SHK Chains: Built for Extreme Heavy Duty

For applications that demand even more robust performance, D.I.D HI-PWR-SHK roller chains feature thicker link plates than the HI-PWR-S chains. Specifically designed to resist the weakening effects of installation and operational fatigue, the HI-PWR-SHK chains offer enhanced tolerance to large shock loads. These chains provide 25% higher tensile strength, and 50% higher allowable load capacity compared to standard roller chains, making them the ideal solution for extreme applications.

These high-strength chains are the go-to choice for heavy-duty, low-speed transmission needs, such as construction machinery, pipe benders, and multi-level parking machines.

For inquiries:

For inquiries:

[email protected] or a.[email protected]

DID EUROPE S.R.L

Via del Fonditore 16, 40138, Bologna

www.dideurope.com

This article is published in Motion+Drives June 2025 issue on page 47-49