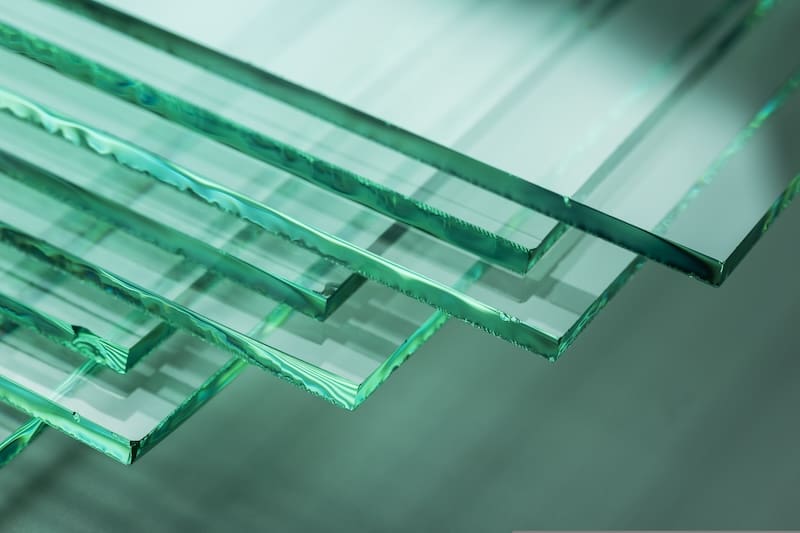

Glass production requires precision at every stage. This is something that we at Megadyne fully understand, along with the other daily challenges glass manufacturers encounter.

With decades of experience, Megadyne has developed a comprehensive portfolio of belts, processing capabilities, and material options tailored specifically for the glass industry.

A new “Glass industry” brochure highlights key applications, including:

- Smooth general conveying

- Precise handling of coated or delicate surfaces

- High-speed, bi-directional movement for cutting and reworking

It also features a case study that demonstrates how we helped solve a real production challenge.

There’s no place like Home

There’s no place like Home

When it comes to furniture and finishes, quality is paramount. Both manufacturers and customers expect nothing less.

Recently, a customer approached us with a pressing issue affecting their transfer conveyor for float glass, one that put both their reputation and sales at risk.

The problem lay with their existing belt, a competitor’s polyurethane timing belt, which was leaving visible marks on the glass. Because the glass was still hot when it came into contact with the belt, the belt’s material softened and deformed under the thermal load, causing damage to the glass product.

To resolve this, we recommended switching to a non-marking, heat-resistant belt designed to protect the glass surface and maintain the brand’s reputation. This solution came with the added benefit of compatibility with standard pulley profiles, ensuring easy integration and minimal maintenance requirements.

For anyone involved in glass manufacturing, this brochure offers valuable insights and practical solutions.

Download the brochure and see how Megadyne can help support your production needs.