Megadyne’s MEGALINEAR P3.3 range

What better stage than Interlift 2025 to showcase Megadyne’s MEGALINEAR P3.3 range? It is designed with four guiding principles in mind: safety, efficiency, space-saving, and quiet.

These aren’t just buzzwords; they define modern elevator expectations. At the heart of it all are often-overlooked components: traction belts.

The MEGALINEAR P3.3 range redefines elevator belts, pushing performance to new levels while addressing common challenges.

The MEGALINEAR P3.3 range redefines elevator belts, pushing performance to new levels while addressing common challenges.

The result? A smoother, quieter, and safer passenger experience, paired with a more efficient and durable system for manufacturers and operators alike.

A solution for every need

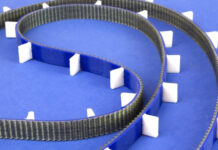

The MEGALINEAR P3.3 range exemplifies Megadyne’s expertise and comes in multiple variations:

- MEGALINEAR P3.3 flame retardant: it provides enhanced fire safety without compromising performance.

- MEGALINEAR P3.3 light: a cost-effective, energy-efficient solution for lighter-duty elevators. Fully compatible with existing 30 mm belt systems.

- MEGALINEAR P3.3 standard widths: available from 25 to 60 mm and with load capacities up to 104 kN. The range offers the flexibility to accommodate a wide variety of applications.

All these belts comply with EN 81-20 / EN 81-50. Standard and flame-retardant versions are ASME 17.1 certified for the US market; the FR range also carries the ASME 17.1 FT1 rating.

More than a belt: a complete system

Designed to reduce the total cost of ownership, Megadyne’s MEGALINEAR P3.3 range supports idler pulleys down to 80 mm and delivers a lifetime of up to 15 years. Extensive testing confirms higher bending durability and breaking strength than alternative solutions.

From cold to hot climates, the MEGALINEAR P3.3 range offers consistent, reliable performance, critical for residential and commercial buildings worldwide. Its smooth, low-noise operation enhances passenger comfort and provides a safer, quieter working environment.

Watch the exclusive video with Megadyne’s expert

Megadyne offers the complete system: belts, pulleys, anchors, and monitoring components. Seamless integration ensures improved efficiency and durability, reduced wear as the components are made to work together, avoiding abnormal stress on the belt or pulley.

Contact Megadyne’s experts for more information!