When a standard belt is not enough

While the line is running at a moderate pace, a standard belt can perform acceptably. The problem arises when the process demands more: higher speed, greater precision, stricter hygiene requirements or the handling of particularly delicate products. In that scenario, micro-stoppages, misalignments, product falls and constant maintenance begin to appear, directly affecting machine availability.

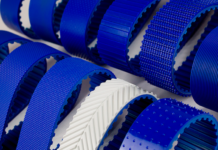

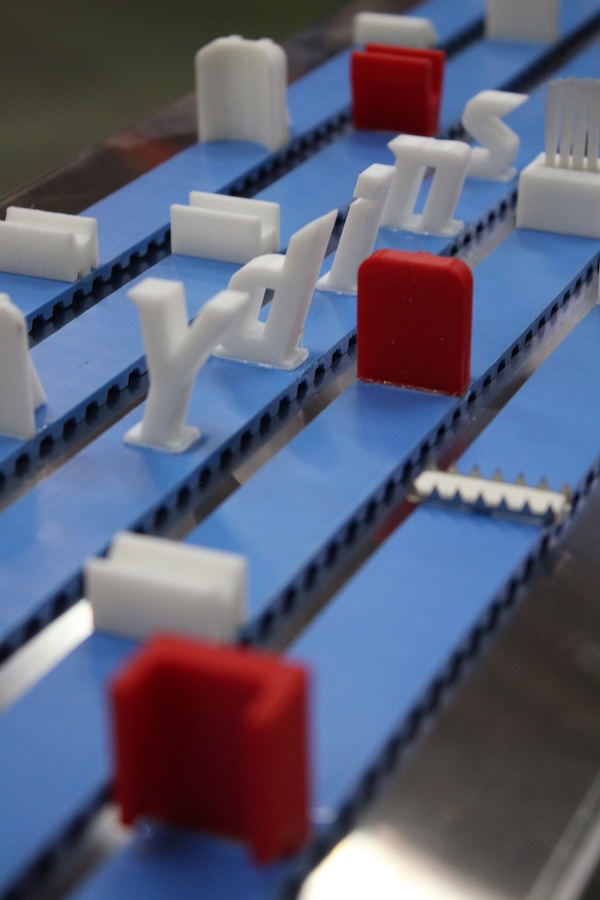

Ydins is positioned precisely at this point: polyurethane timing belts designed to measure, combining coatings, cleats, machining, inserts and jointing systems to adapt to the real conditions of each industrial application.

Why a standard belt falls short

A standard belt is sized according to dimensions and tooth profile, but it does not take into account the product, the environment or the specific dynamics of the line. The usual consequences are:

- Inadequate grip depending on the material or type of packaging.

- Loss of product stability, especially with light packs, unstable formats or inclined conveying.

- Premature wear and the need for frequent replacements.

- Limitation of line speed to avoid incidents and rejects.

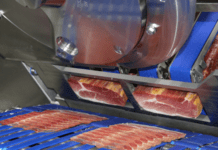

- Difficulty in meeting hygiene and safety requirements, especially in food and pharmaceutical applications.

In operational terms, this results in lower productivity, a higher reject rate and a total operating cost that is higher than expected.

What a custom-made Ydins belt provides

Four key areas of differentiation compared to a standard belt:

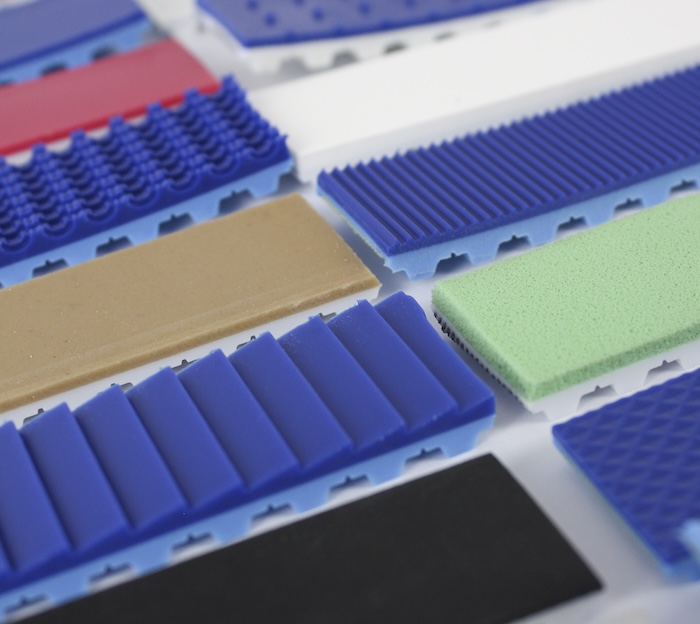

- Belts with coatings

They adjust the coefficient of friction, hardness and contact surface to the type of product and sector, including configurations suitable for food contact where required.

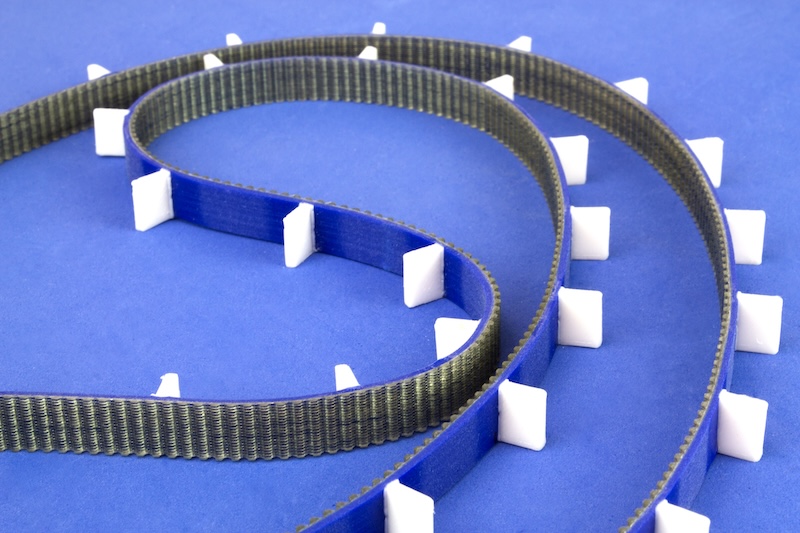

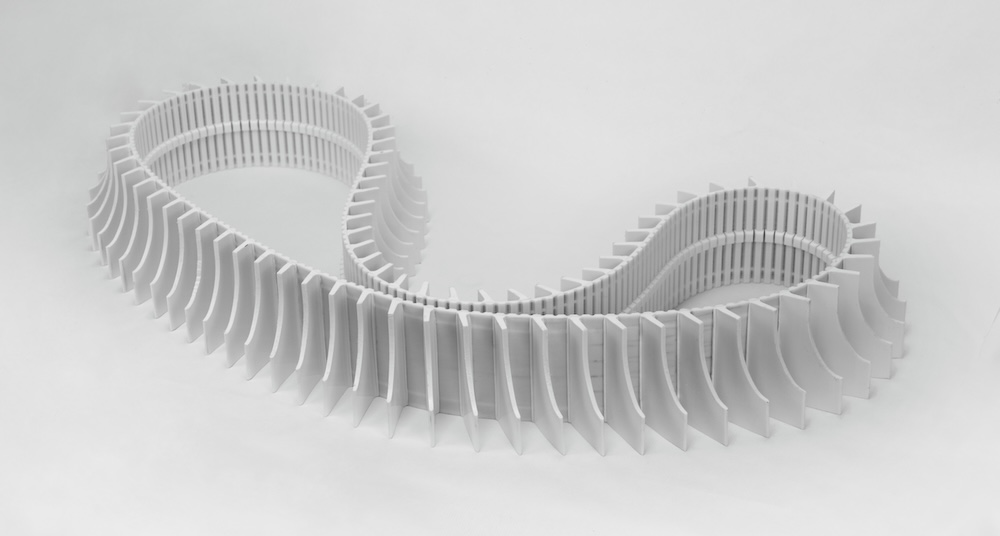

- Belts with custom cleats

Designed according to the shape, weight and spacing of the products, they improve grip and positioning, and are particularly effective in inclined conveying or with unstable parts.

- Machined belts

They incorporate specific machining (grooves, recesses, guide seats, etc.) that allow the belt to be adapted to the machine kinematics and to the rest of the process elements, reducing deviations and misalignments.

- Belts with inserts and false teeth

They enable precise fastening and reconfiguration of cleats and profiles, maintaining a synchronous and stable drive even in applications with high positioning demands.

- Integrated customisation combining design options

By combining different customisation options on the same belt — coatings, cleats, machining, inserts and false teeth — Ydins can fine-tune the interaction between belt, product and equipment, achieving an even closer match to process requirements and providing additional flexibility for future product or format changes.

From standard component to strategic solution

When the line is operating close to its production limit, the belt ceases to be a simple spare part and becomes a key element in overall system performance. Ydins custom-made belts increase stability, speed and reliability wherever the standard belt becomes a bottleneck, adapting the design to the product, the machine and the regulatory environment of each plant.

The result is a solution that, beyond merely replacing a belt, directly helps to improve availability, quality and the total cost of the process.

If you recognise any of these symptoms in your process, get in touch with Ydins and we will work with you to determine which type of custom belt can best optimise your line’s performance.