Motion+Drives

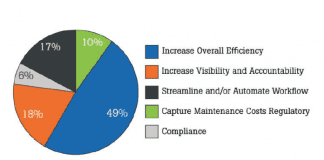

How CMMS helps drive operational excellence

Gone are the days when your team could solely rely on paper-based maintenance solutions. In today’s fast-paced business environment, an effective Computerized Maintenance Management...

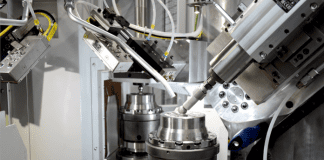

Innovative machine solution for run production: Spherical Parts in Shortest Cycle...

Based on the high-precision Sphero machine tool, Thielenhaus Microfinish has developed a highly efficient two-step solution which performs the entire fine-finishing process for spherical...

Know the 4 Winding Failures in AC Electric Motors

Did you know that the vast majority of electric motor failures are preventable?

There are some failures you can't prevent because everything has a limited...

NSK saves nearly €3 million at steel mill

A steelmaker based in Poland is saving nearly €3 million per year after switching to NSK´s sealed-clean KVS bearings in its roll mill. Such...

How many times can you repair an Electric Motor?

How many times can you repair an electric motor? It's a question that comes up from time to time and the answer is actually...

Pumping Systems on VFD Need Bearing Protection

In most pump applications, it is not always necessary to run the pump at full speed. Flow rate has traditionally been decreased with flow...

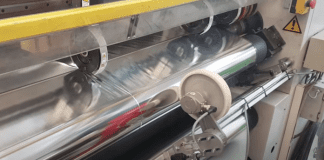

Roll feed and winding web length measurement made easy: Wachendorff LMSMA...

Extensively proven over several years for precise measurement of web length, position and speed in numerous roll winding and web-based machinery applications, Wachendorff’s LMS...

Greater working radius: Schaeffler gives cobots greater range with plug-and-play linear...

Plug-and-play linear actuators from Schaeffler add horizontal axes to extend the working range of robots and cobots

Ready-to-install turnkey system can be tailored...

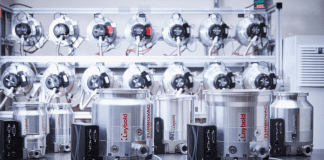

Two new turbomolecular pump sizes from Leybold for R&D and industrial...

For more variability - the TURBOVAC i/iX family grows

In June 2020 the vacuum specialist Leybold has expanded its TURBOVAC i/iX series - 90, 250,...

SKF factories to be carbon neutral by 2030

Since 2015, SKF has decreased its manufacturing carbon footprint by 36% and is already operating two carbon neutral factories. Today, SKF announces its aim...