Tag: Ultrasound

3 Ways to incorporate Ultrasound into lubrication testing

When a bearing lacks proper lubrication, damaging friction can occur. Ultrasound equipment allows inspections to read the decibel (dB) levels of under or over-lubricated...

Improve Lubrication Practices with Ultrasound

Keeping a handle on lubrication is easy, right? All one needs to do is make sure the right lubricant is used in the right...

Bearing Workshop Took Place Succesfully During WIN Eurasia 2018

Bearing Root Cause Failure Analysis and How to Use Ultrasound to Upgrade Lubrication Practices workshops took place successfully during the WIN Eurasia 2018 event in Istanbul on...

Workshops: Bearing RCFA & How to Use Ultrasound to Upgrade Lubrication...

Bearing Root Cause Failure Analysis Workshop details:

Presented by: Per Arnold ELGQVIST 16 March 2018 Friday, during WIN exhibition in Istanbul

Workshop Goals

To emphasize the importance...

Who Uses Ultrasound for On-Condition Lubrication of Bearings?

Who uses ultrasound for on-condition lubrication of bearings? The digital version of SDT's 2017 Ultrasound Lube Technician's Handbook is now available for FREE download....

HOW TO USE ULTRASOUND TO UPGRADE LUBRICATION PRACTICES

Avoid these 3 mistakes when lubricating bearings

Friction is all around us. Without it we would find it very difficult to run, walk, or even...

How Ultrasound Bearing Inspection Works

Mechanical movements produce a wide spectrum of sound. One of the major contributors to excessive stress in machinery is friction. Ultrasound instruments detect friction. ...

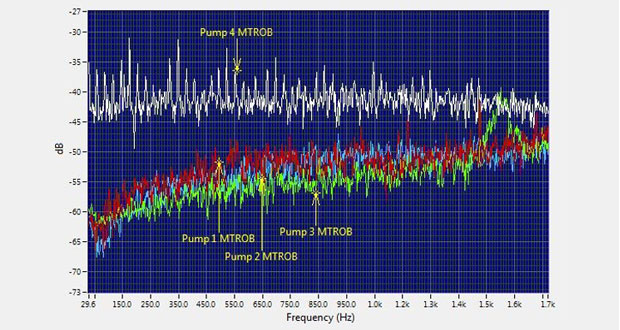

Slow Speed Bearing Monitoring

by Adrian Messer, CMRP

UE Systems, Inc.

Introduction

As maintenance and reliability professionals, we must ensure that the assets that we are responsible for are operating...

Preventing Bearing Failure Using Ultrasound

UE Systems has a wide range of instruments, both analogic and digital, which are perfect for bearing inspection and bearing condition monitoring using Ultrasound...

3 Ways to Incorporate Ultrasound Into Lubrication Testing

When a bearing lacks proper lubrication, damaging friction can occur. Ultrasound equipment allows inspections to read the decibel (dB) levels of under or over-lubricated...