By Mark Bos, Fenner Drives

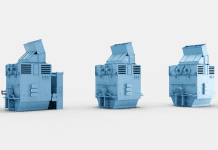

A problem commonly encountered in the manufacturing of gearboxes is filling the last gap in the gear shaft assemblies.

The accumulated tolerances of the many components can result in a range of gaps too wide to be met with a single size spacer. Filling the gap accurately and completely is critical to reliable, long-term operation of the powertrain or gear box.

The accumulated tolerances of the many components can result in a range of gaps too wide to be met with a single size spacer. Filling the gap accurately and completely is critical to reliable, long-term operation of the powertrain or gear box.

Traditionally the gap is filled with a combination of shims, or the gap is measured, and a thick spacer is ground down to a finished thickness. Both options are time consuming and slow the final assembly rate. They also introduce a significant chance for error.

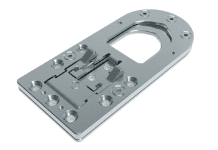

National Bearings, a product line of Fenner Drives, designs and produces spacers to solve this problem for OEMs and is currently doing so for a major player in the industry. The custom spacers are manufactured in a range of precise thicknesses to fill the last gap with a single spacer, no matter how wide the gap that is produced by the combined components.

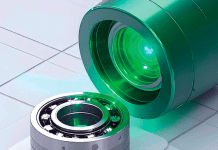

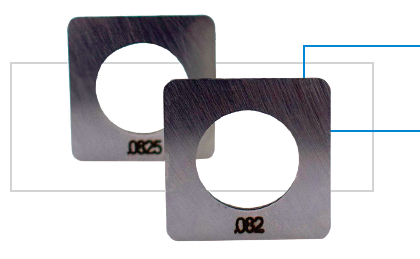

Made from stamped steels that are designed for extreme duty applications, spacers can be nearly any shape from a simple round washer to more complex geometries to fit any constraint. They are hardened and ground to precise thickness and flatness tolerances. Finally, the spacers are then laser engraved or color coded for easy and error-proof identification.

Technical Details

Typical materials: Bearing steels such as UNS 1050, 1074, 8620, 52100 or corrosion resistant steels including 302/304, 420 or 440C

Typical materials: Bearing steels such as UNS 1050, 1074, 8620, 52100 or corrosion resistant steels including 302/304, 420 or 440C- Hardening up to 60 HRC

- Surface finishes from .8-.2 micrometer RA

- Thickness, flatness, and parallelism to .003 mm

The distribution of the gap thickness in gearbox assemblies is usually uneven across the range of component stack ups, with a few specific sizes making up a majority of the usage. Precision ground stampings allow for the cost efficiency of high-volume manufacturing and the wide range of thicknesses usually provided by machining. That way it is possible to order smaller quantities of the infrequently used sizes while taking advantage of the lower pricing of those sizes requiring higher volumes. More technical details are listed below or can be consulted at www.fennerdrives.com.

This article is published in MOTION+DRIVES Oct-Nov-Dec 2021 issue.

Download the .pdf version or Read the eMagazine

Typical materials: Bearing steels such as UNS 1050, 1074, 8620, 52100 or corrosion resistant steels including 302/304, 420 or 440C

Typical materials: Bearing steels such as UNS 1050, 1074, 8620, 52100 or corrosion resistant steels including 302/304, 420 or 440C