Motion+Drives

Fersa at Automechanika 2018 in Frankfurt

At this year’s Automechanika in Frankfurt, Spanish bearing manufacturer Fersa Bearings presented the potential of its new innovative product range and its latest wheel...

Eliminate Lubricants

Eliminating lubricants can improve machine performance as many greased and oiled bearings fail prematurely due to inadequate lubrication.

Reasons for inadequate lubrication may include

Lack...

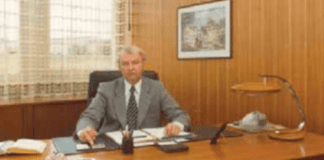

A Bartlett Bearing Vice President Retires

After almost four decades with Bartlett Bearing Company, Inc. Mr. Bill Potts Vice President of Operations has decided to retire. Bill’s commitment and expertise...

US – China Bearing Tariffs: What’s Your Strategy?

Author: Dave Hull, founder and president of PRECISION COMPONENTS, INC

Are you confused by the 301 tariffs the US has imposed on China? You are...

European Bearing Industry Import, Export & Production statistics

European Bearing Market Research

Distribution & Manufacturing Statistics

Data about the bearing distribution market and individual Import, Export, Manufacturing statistics for 28 EU member countries.

The bearing market is...

JESA has lost its founding father

Joseph Egger has had a lasting impact on the industrial footprint of Fribourg following the creation of the precision bearing manufacturer JESA, which will...

NSK announces significant extension to ProKIT range

In a major announcement at this year’s Automechanika Frankfurt exhibition, NSK Europe released a significant extension to its available range of products for the independent...

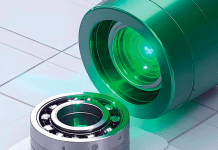

OAV Air Bearings announce A&AT as distributor of South Korea

OAV Air Bearings - the leading manufacturer of the recently advanced frictionless air bearing technology - is pleased to announce the addition of A&AT as...

What makes a quiet bearing?

Noise in a bearing can be caused by a number of factors, but almost all are related to vibration. Here, Chris Johnson managing director...

HepcoMotion is playing a key role in a notoriously harsh slate...

The ability to run without lubrication, in a harsh environment, with a high duty cycle were the performance demands placed on linear motion expert...